What Is VMMS? And Why Now?

The built environment is experiencing growing pains.

“Digital Transformation.”

“IoT.”

“Industry 4.0.”

“Inverted Rotational Connectivity.”

OK, that last one was made up. But the other phrases weren’t.

They each are tech-y terms that promote improvement, carry nuance, and provoke wonder in the realm of facility management (FM). Every sector is experiencing changes that not only challenge the status quo, but also pave the way for groundbreaking solutions. (Here’s a recent post we did that helped define those new-era buzzwords.)

Whether it’s maneuvering the obstacles of implementing digital transformation, the pressures of selecting the right strategies, or working together in an integrated manner, the new frontier of Industry 4.0 is rapidly altering the management landscape, leaving organizations with questions to answer – and diminishing time to solve them.

Technicians and upper management alike are asked to do more with less. And as the ground shifts under their feet, decision makers are searching for better, more connected solutions for their operational needs.

“It’s hard to navigate any situation without visual context,” states Aetos Imaging’s CEO Connor Offutt. “In operations, in production – at any level of management – the ability to actually see your surroundings can bring true clarity to an entire organization.”

That’s the vision that Aetos is capturing across the built environment.

Our revolutionary approach is reimagining how facilities can be visually managed across the globe. It’s never been done before, so we figured it needed a name.

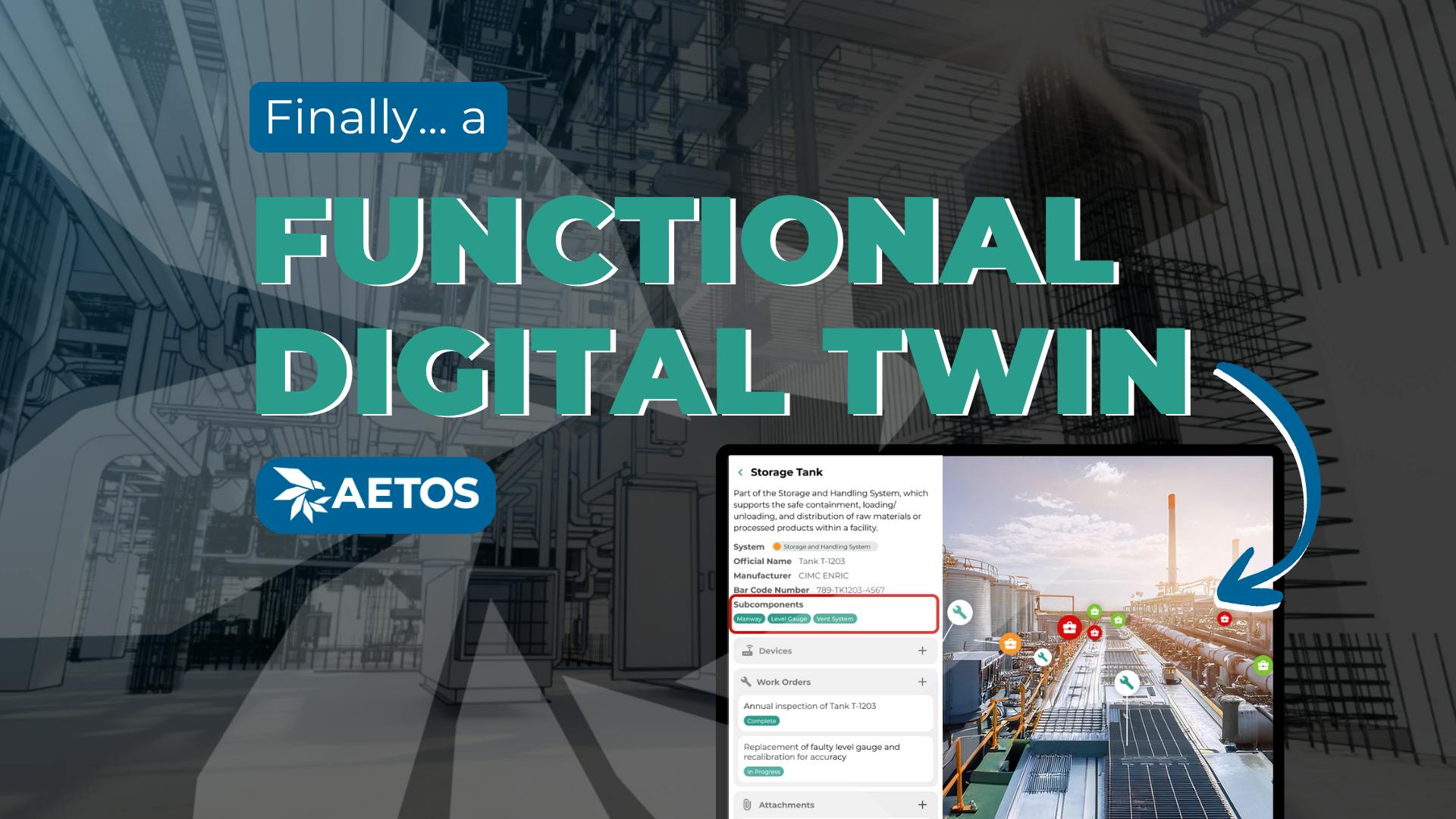

Introducing the world’s first VMMS: a Visual Maintenance Management System. Built for the operator, and designed to deliver clarity, connection, context, and exceptional management capabilities.

What is a VMMS?

As previously mentioned, VMMS stands for Visual Maintenance Management System, an innovative leap forward in facility management. It’s a visual upgrade from the more traditional Computerized Maintenance Management Software (CMMS).

Unlike CMMS, which primarily relies on text, spreadsheets, and static data, VMMS integrates dynamic, visual information, providing a 3D, interactive environment of all assets, performance data, and physical models.

Basically, a VMMS is a comprehensive, digitized version of a facility - past, present, and potential.

This integration unlocks a variety of use cases for stakeholders across a company.

By granting visual context for procedural needs, a VMMS allows personnel to see their operational data in real time, train and retrain within an immersive environment, interact with equipment and assets - and much more - in order to make better, faster, more-informed decisions.

Imagine being able to virtually navigate through a facility, identify issues, create a visual work order, and troubleshoot or collaborate with your team all from a single pane of glass. “VMMS not only simplifies complex processes, but also enhances the accuracy and efficiency of facility operations,” explains Offutt.

Aetos is pioneering this VMMS technology. We give your team a holistic view of your assets, facilities, and portfolio. This breakthrough unlocks a new way of management by giving literal sight into every corner of your operation.

The Evolution of Maintenance Management

The concept of maintenance management isn't new, yet its methods have dramatically evolved over the decades.

What started as rudimentary pen and paper scribbles has improved to sophisticated digital solutions. As such, manufacturing practices – and the management of the facilities themselves – have shifted with the advancement of technology. (This article by control.com is a quick and easy-to-understand breakdown of the four industrial revolutions we’ve experienced to date.)

Initially, facility management was reactive, focusing mainly on addressing issues as they occurred. The “firefighting approach” to FM was a common method as management teams spent their days solving critical problems that came up (and sometimes these problems were actual fires).

As technology progressed and proposed improvements were tested, the built environment moved towards a more proactive approach.

Today, standard management practice utilizes databases and digital tracking to monitor and maintain equipment before failures can disrupt production. These methods are commonly computerized and bundled into a management tool known as a CMMS - or Computerized Maintenance Management System.

The goal of a CMMS is to optimize the processes and procedures - as well as track and document - predetermined tasks and management elements for all types of facilities. This was a powerful tool for better operations in the built environment as it unlocked new capabilities like tracking and monitoring work orders, scheduling maintenance, documenting equipment health, budgeting more effectively, and even detailing component inventory.

However, in any growing industry, advances in technology and analytics drive change. Eventually, companies sunset outdated systems and adopt better processes.

It was only a matter of time before CMMS platforms became obtuse and inefficient for the advancing needs of our facilities.

The next iteration of facility management has arrived, born out of Industry 4.0’s principles of optimized data, streamlined operations, and unbridled connectivity.

“VMMS represents the next step of this evolution, leveraging cutting-edge visual technology to transform maintenance, training, monitoring, and decision making into a strategic advantage,” states the Aetos CEO.

As a visual platform built for the operator, Aetos is revolutionizing the entire ethos of FM into a predictive and preventative practice. We provide a cloud-backed, bi-directional connection that allows the workforce to access their facilities from any device, anytime, anywhere. (Sounds in line with the Industry 4.0 trend.)

Our intuitive VMMS is accessible with mobile devices, providing a single pane of glass for facility teams to manage their assets, work orders, maintenance needs, SOPs, training materials, data capture, historical source of record, and much, much more.

By providing a detailed, immersive environment, we’re giving management teams a comprehensive solution to better access and leverage critical data, technical knowledge, SOPs, asset health, and production performance.

With mobile capabilities, Aetos can put your facility in your pocket.

Why VMMS Now?

The timing for VMMS couldn't be better.

Several converging technological advancements make it possible and necessary. “High-definition cameras, cloud computing, wireless sensors, and mobile technology have all played a part in the development of VMMS, allowing complex visual data to be processed and accessed remotely in real-time,” Offutt explains. “The market has also clearly indicated that VMMS technology is widely needed across multiple industries.”

These synthesized technologies enable VMMS to thrive by facilitating large-scale, detailed visualizations of facilities that were previously both impossible and impractical.

The increasing complexity of modern facilities – which contain thousands of interconnected systems requiring precise coordination – demands a more sophisticated approach to maintenance management as well. Industry 4.0 continues to push the limits of smart manufacturing, real-time decision making, and increased productivity.

VMMS meets this need by providing an extensive, easy-to-navigate interface that visually reflects the complexity of real-world operations.

Soon, there will be another iteration of VMMS that leverages faster scanning technologies, augmented equipment support, visualized data readings, and even more connectivity.

Additionally, with higher productivity initiatives and new sustainability measures, organizations are being asked to do more with less. Unfortunately, the drive in digital transformation can leave our best technicians behind.

Aetos was built with the operator in mind. By providing a visually detailed, immersive environment for technicians and managers, we’re giving operations teams the context they need to get. work. done.

As it’s critical for manufacturing companies to adapt to Industry 4.0 capabilities, Aetos is intent on capturing institutional knowledge and delivering best practices without compromising productivity.

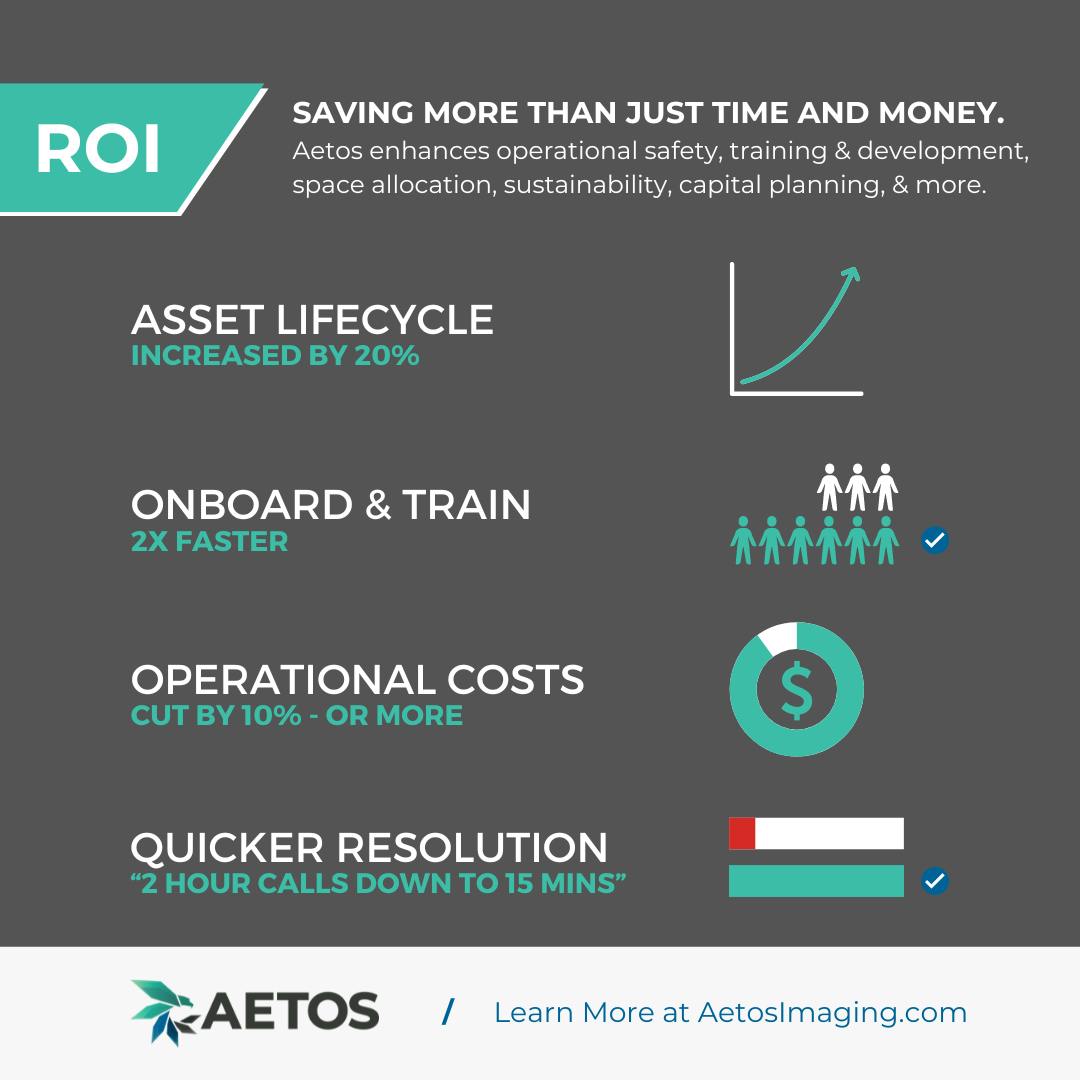

The Aetos VMMS is helping companies around the world cut onboarding times by 50%, decrease operational downtime & costs by 20%, increase productivity by 15+%, and eliminate non-visualized work orders by 100%.

Benefits of VMMS

TL;DR: VMMS is impacting multiple businesses across multiple industries with multiple use cases for each. Facility managers nationwide are convinced the power of sight is just too potent, too practical, too pragmatic to not embrace and employ.

How would your operations change if you were given the power of sight when managing and servicing your facility?

That question was the driving force behind the vision of Aetos.

We rolled out VMMS 8 months ago. The feedback has been monumental (and affirming) in our quest to be the best possible management platform for technicians and their operations teams.

Several tangible benefits have surfaced, and are already seeing compelling use cases pop up across multiple industries:

A top 3 energy firm is leveraging our 3D visual context for faster troubleshooting times - dropping 2 hour calls down to 15 minutes. That’s real-time revenue being optimized across an expansive portfolio where safety, efficiency, production, and accessibility are paramount.

A nationally recognized quick service restaurant organization has partnered with Aetos to visualize their assets across hundreds of their regional stores. The visual context we’re providing is on track to save this organization millions of dollars per year, and there’s enough of a mutual benefit to eventually expand to thousands of locations nationwide.

One of the premier property management firms on the East coast is leveraging Aetos for expedited training and knowledge transfer to their on-site building personnel. They’re using our VMMS for an immersive platform to specifically and thoroughly deliver SOPs, training modules, and maintenance guidance. They’re providing powerful access to exact institutional information across their portfolio.

One of the nation’s top energy producers is utilizing Aetos to enable complex wayfinding across their 33 acre facility. In addition, they’re leveraging best-in-class, site-specific training for their employees to ensure and govern safety procedures are met at all times for all operations.

(We could go on, but this blog does have a word count.)

The common consensus? Operations teams are loving the practicality of being able to see their facility like never before.

According to Offutt, “Aetos is simply a comprehensive, visual platform. This integration allows facility managers to anticipate problems before they occur, plan maintenance activities efficiently, track live and historical data throughout a facility, and promote operational excellence across production, training environments, safety measures, sustainability initiatives, asset monitoring, and overall facility lifecycles."

Yeah, it’s a lot.

Aetos is built for the operator with the sole intention of providing visual context to all the literal (and figurative) nooks and crannies of a facility.

Implementation and Adoption Challenges

Historically, organizations that intentionally adopt valid technological advancements experience better results and more sustainable operations. And as we move along the exponential uptick of Moore’s law, the time for better, more connected management has arrived.

However, there are relevant challenges when implementing a VMMS.

A hurdle for some organizations is the difficulty in integrating with existing legacy systems. New software often requires abandoning specialized knowledge or complications when integrating “the old” with “the new.” This challenge can lead to delays in project timelines and increased costs, not to mention uncertainty in the improvement process across a workforce.

Another might be navigating the process of sunsetting older technologies or training materials, which necessitates careful planning to avoid disrupting ongoing operations. Such transitions must also consider the retention of valuable data and insights from the previous systems. And if an organization has strong ties to regularly used training – even if it’s a little outdated – there can be hesitations for trying something new.

Finally, there are concerns over ensuring whatever new solution that is brought in actually delivers on its promise. Flashy colors or exciting animations can gloss over glaring gaps in any given software. Organizations can be bearish on new management software due to the novelty of Industry 4.0 and its nuanced disposition – and rightfully so.

All of these challenges are valid. Change - in any setting - comes with growing pains more often than not.

The good news is we have worked with partners to navigate each of these challenges.

Aetos integrates with legacy EAM systems. (For the IT nerds: if it has an open API, we can integrate.)

Aetos leverages already-in-place monitoring devices. (And if your facility is a little late to the IoT game, we have best-in-class, non-invasive wireless sensors that can monitor all of your equipment, set at your specific parameters.)

Aetos takes what you already do well and enhances its effectiveness by leveraging visual context for your teams’ benefit. This allows your organization to take what you do well and make it better.

This means our identity is anchored in offering practical, pragmatic use cases for our partners. To be a good fit, a VMMS must be intuitive for the on-site technician as much as it is for upper management teams. The best software is beneficial and natural to stakeholders at every level.

It bears repeating: Aetos is built for the operator, not the billboard.

Overcoming implementation and adoption challenges requires thoughtful strategy, careful planning, and a partner who is willing to assist you on your digital transformation journey. Let us be your guide throughout the entire process.

The Future of FM with VMMS

As we continue navigating the future of facility management, VMMS stands out as a transformative iteration. But there will be even more improvements ahead.

The integration of IoT, 3D image capture, cloud computing, and even AI & Machine Learning (ML) could further enhance VMMS capabilities.

As industries are looking to be more productive with less resources, there’s a natural progression to more autonomous FM systems. These systems could predict failures before they happen, automate routine maintenance tasks, and continuously improve – and maybe even send out humanoid robots to ensure Inverted Rotational Connectivity is executed.

“Sight for operations teams is the practical solution. VMMS is setting the stage for a smarter, more connected approach to maintaining and optimizing facilities. Aetos hopes to be at the forefront of the next generation of operational excellence and possibility," concludes Offutt.

As we embrace these exciting advancements, facility managers and industry professionals are encouraged to explore how VMMS can be integrated into their specific operations.

How could a VMMS impact the landscape of facility management in your industry?

How can visual context unlock more productivity for your teams?

How would your operations change if you could access your entire facility from your pocket?

That’s the power of Visual Management. That’s the power of Aetos.